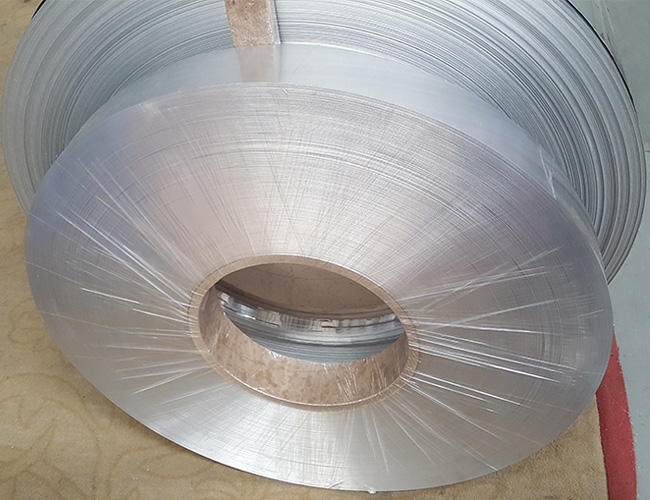

6063 Flat Aluminium Strip for Sale

What is 6063 thin aluminum strip

6063 alloy belongs to Al-Mg-Si high plasticity alloy, featuring superior processing performance, excellent weldability, extrudability and electroplating property, good corrosion resistance, toughness, easy polishing, good coating and anodizing effect and no tendency of stress corrosion cracking. 6063 aluminum alloy is available in several different temper grades- 6063-T6, 6063-T651, 6063 T7351 and 6063-O. It is most commonly available as T6 temper and has good formability in the T4 temper.

6063 aluminum alloy properties

Property | 6063-T5 | 6063-T6 | 6063-T832 |

Tensile strength | 186 Mpa | 241 Mpa | 290 Mpa |

Yield strength | 145 Mpa | 214 Mpa | 269 Mpa |

Modulus of elasticity | 68.9 Gpa | 68.9 Gpa | 69.0 Gpa |

Aluminium 6063 chemical composition

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | |

Each | Total | |||||||||

6063 | 0.20-0.6 | 0.35 | 0.10 | 0.10 | 0.45-0.9 | 0.10 | 0.10 | 0.10 | 0.05 | 0.15 |

Specification

Item | 6063 Aluminum Sheet | 6063 Aluminum Strip |

Thickness | 0.2-200 mm | 0.2-6.35 mm |

Width | 30- 2500 mm | 55-2500 mm |

Length | 500-13000 mm | According to customer requirements |

Application

6063 aluminuim is a medium-strength alloy, commonly used in building doors and windows, curtain walls, various industrial aluminum profile frames, aluminum radiators, railings, signage frames, mechanical parts, irrigation pipes, electrical/electronic equipment accessories, furniture accessories, etc.

The 6063 aluminum plate has high hardness and strong resistance to hardening, and will not break easily, which can ensure that the liquid in the container is safe and sound. 6063 aluminum alloy belongs to the aluminum-magnesium-silicon alloy. It is a heat-treatable strengthening alloy with medium strength. It has relatively stable mechanical properties and good tensile strength. It can resist external pressure and minimize the deformation of the container itself.

The hardness and the tensile strength of 6063 aluminum alloy can be said to be important factors that determine the compressive strength of ship containers. 6063 aluminum can be processed into various profiles. After heat treatment and strengthening, 6063 aluminum can obtain good mechanical properties, physical properties and corrosion resistance, and is more suitable for structural materials of marine vessels.

The aluminum alloy railing is made of 6063 industrial aluminum. After extrusion, aging, melting, and high-temperature electrostatic spraying, it is made with a new classical buckle combination technology. The aluminum alloy guardrail does not need welding, wire joints, and corner code connections.

6063 VS6061 VS6013

The heat dissipation effect of 6063 aluminum alloy is better than that of 6061 aluminum alloy. The heat dissipation of 6063 aluminum alloy is 0.2~0.22kw/(m ℃), while that of 6061 aluminum strip is less than 0.2. Therefore, on the market, 6063 aluminum is used to make radiators.

In terms of material strength, no matter which treatment process is used, the strength of 6013 alloy is higher than that of 6063 alloy. 6013 aluminum alloy is one of the most advanced aluminum alloys in the world today. It has outstanding formability (castability, plastic formability, weldability), medium specific strength, good corrosion resistance, superior damage tolerance, excellent thermal exposure stability and other performance. It is widely used in large civil aircraft, military carrier aircraft, rail transit and other fields.

Why choose Haomei Aluminum

1. Advanced modern equipment

Haomei Aluminum has 6 semi-continuous casting production lines, 10 continuous rolling production lines, 7 cold-rolling mills, 10 foil rolling mills, stretch-bending straightening and cleaning machines, flying shears and slitting machines, thick foil shears, longitudinal shears, ( 1+ 4) hot rolling production line and other equipment.

2. Strict control of the production process

Haomei Aluminum has established advanced quality inspection laboratories, chemical analysis laboratories, oil product analysis laboratories, tensile laboratories, microscopic analysis laboratories, etc.

3. Control product quality from the source

We have set extremely strict standards for the raw materials we use, and more than 95% of the key raw materials purchased come from well-known companies.

Original source: https://www.aluminumstrip24.com/products/6063-aluminum-strip.html

Tags: thin aluminium strip,

Previous: 6061 Thin Aluminum Strip

Next: 6082 Aluminum Strips for Sale