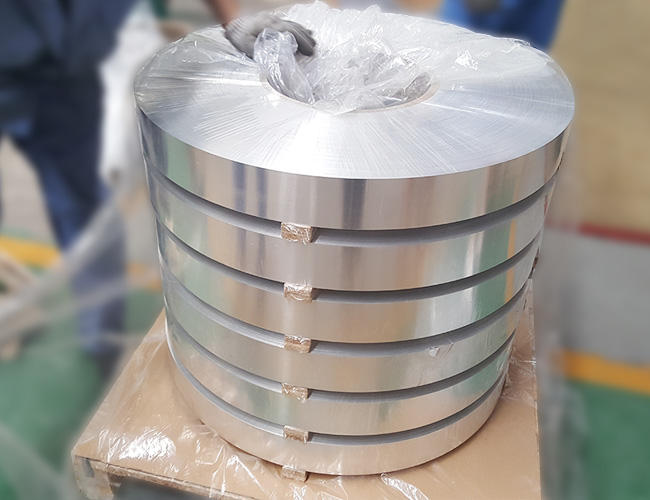

6082 Aluminum Strips for Sale

What is 6082 aluminum alloy

6082 aluminum alloy is a typical heat-treatable aluminum alloy with medium strength and good welding performance, formability and corrosion resistance, and is often used in transportation and structural engineering industries such as bridges, cranes, roof structures, transport planes, and transport ships. It is an ideal raw material for manufacturing high-speed ship components.

6082 aluminum is a 6000 series aluminum alloy. Both magnesium and silicon have significant alloying effects. 6082 is the Aluminum Association (AA) designation for this material. In European standards, it will be given as EN AW-6082. AlSi1MgMn is the EN chemical name. H30 is a British Standard (BS) designation. A96082 is the UNS number. Another popular 6xxx aluminum strip is 6061 aluminum strip.

Aluminium 6082 properties

Chemical composition

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Other | Al | |

6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41-1.0 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | - | each | total | balance |

0.05 | 0.15 | |||||||||||

Physical properties

Density | 2.70 g/cm3 |

Melting point | 555°C |

Thermal expansion | 24 x10^-6 /K |

Elastic Modulus | 70 Pa |

Thermal Conductivity | 180 W/m K |

Resistivity | 0.038 x10^-6 Ω .m |

Specification

Alloy | 6082 |

Thickness | 0.3-8 mm |

Width | 100-2650 mm |

Tempers | O, T4,T6, T651 |

Main tempers

T6: Solution heat treatment and artificial aging

O: Soft

T4: Solution heat treated and naturally aged to a substantially stable state

T651: Solution heat treated, stress relieved by stretching, then artificially aged

6082 thin aluminum strip mainly has four states: O, T4, T6, T651. 6082 aluminum alloy combines excellent corrosion resistance, formability, brazeability, weldability and machinability. The state of alloy 6082-O and 6082-T4 is suitable for bending and forming occasions, while 6082-T5 and The 6082-T6 state is suitable for good machinability requirements.

6082 alloy usually has good processing characteristics and anodic reaction performance, and is widely used in mechanical parts, forgings, railway structural parts, commercial vehicles, shipbuilding and other fields.

The strength coefficient of welded joints of 6082-T6 aluminum alloy is 0.6, and the minimum tensile strength of 6082-T6 aluminum alloy is 300 MPa, so the tensile strength of welded joints should be higher than 180 MPa. After testing, its tensile strength meets the requirements of the standard.

The bending angle of the side bending test reaches 180°, no cracks are found, which meets the requirements of relevant standards. It can be seen that the joints of 6082-T6 thick aluminum alloy FSW welding have good mechanical properties.

Applications

6082 is typically used for:

~ High stress applications

~ Truss

~ Bridge

~ Cranes

~ Transportation Application

~ Ore Machine

~ Beer barrel

~ Milk blender

Original source: https://www.aluminumstrip24.com/products/6082-aluminum-strip.html

Tags: aluminum strips for sale,

Previous: 6063 Flat Aluminium Strip for Sale

Next: Super Hard 2024 Aluminum Strip