Aluminum Strip For Transformer

Bulk buyers often face the same question: which aluminum strip for transformer is truly fit for windingespecially when conductivity, thickness tolerance, and surface quality can directly affect heat rise, losses, and production yield. This guide clarifies the most common selection points and purchasing checks for transformer winding aluminum strip in coil form.

1) What aluminum strip is used in transformers (and why)

In many distribution and power transformer designs, aluminum strip is used as winding conductor because it offers a cost-effective balance of conductivity, weight, and formability. Compared with copper, aluminum typically reduces material cost and weight, while requiring thoughtful design to manage cross-sectional area and joining methods.

For bulk procurement, the real decision is not aluminum vs. copper, but which electrical grade aluminum strip fits your winding process and performance target:

Conductivity & temperature rise: Higher purity aluminum generally delivers better conductivity and more stable winding resistance.

Formability: Winding needs consistent elongation and controlled work-hardening to prevent edge cracking.

Surface & edge quality: Burrs, scratches, or oxide issues can damage insulation paper/film and increase failure risk.

Dimensional stability: Tight thickness and width tolerances support repeatable turns and compact coil build.

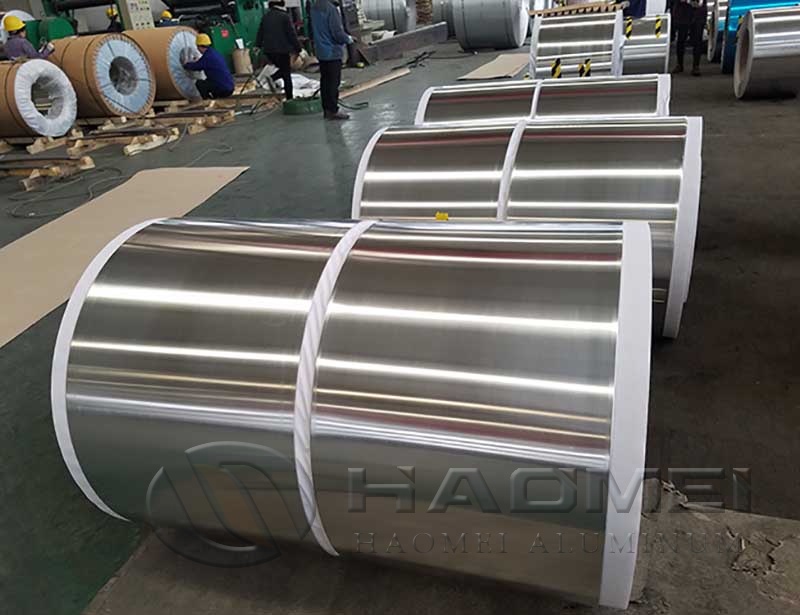

If you are sourcing from a mill or converter, prioritize suppliers that regularly produce aluminum strip coil for electrical winding applicationsnot just general-purpose strip.

2) Common grades and temper for transformer winding aluminum strip

Most transformer winding strip is sourced from high-purity 1xxx series aluminum due to its electrical performance and ease of processing.

| Application focus | Typical alloy | Typical temper | Why its chosen | Notes for buyers |

|---|---|---|---|---|

| Standard distribution transformer windings | 1050 / 1060 | O (annealed) | Good conductivity and excellent formability | Popular for stable winding without cracking |

| Higher conductivity requirement | 1070 | O | Higher purity higher conductivity | Verify conductivity test method & certificate |

| Process needs stronger strip (less deformation) | 1050 / 1060 | H12/H14 (limited) | More strength, less stretching | Confirm bending radius and winding equipment compatibility |

Most winding lines prefer O temper because it reduces risk of edge cracking and helps maintain insulation integrity during tight bending.

3) Specification checklist: thickness, width, tolerance, and surface

When buyers say we need aluminum strip for transformer, the hidden challenges are often tolerance and surface requirements. Use a purchase checklist that matches your winding tooling.

Typical spec ranges (buyer reference)

Thickness: commonly 0.203.00 mm (many projects fall in 0.302.00 mm)

Width: commonly 10160 mm (custom widths available)

Inner diameter (ID): often 150/200/300/400/500 mm depending on coil handling

Surface: clean, uniform, free of heavy scratches, roll marks, oil stains; controlled oxide

Edges: deburred, slit edge quality consistent; no sharp burrs that cut insulation

Recommended purchasing tolerances (example guidance)

Exact tolerances depend on your coil design and standard used (EN/ASTM/GB). As a buyer, specify target values clearly:

| Parameter | Recommended control for winding | Why it matters |

|---|---|---|

| Thickness tolerance | tighter than general-purpose strip (project-defined) | Impacts turns count, fill factor, and losses |

| Width tolerance | stable across coil length | Prevents coil build variation and insulation misalignment |

| Camber/flatness | controlled to your winding machine | Reduces tracking issues and coil distortion |

| Burr height | minimal, measurable | Prevents insulation damage and partial discharge risk |

If you need help defining tolerances, align them with your winding equipment capability and insulation system thickness.

4) Quality control tests bulk buyers should request

To reduce incoming inspection disputes and production downtime, request objective testing with each lot of transformer winding aluminum strip:

1. Chemical composition certificate (alloy verification).

2. Conductivity test (often %IACS): confirm test standard and sampling plan.

3. Mechanical properties (tensile strength, elongation) for your chosen temper.

4. Dimensional report (thickness/width profile across the coil; coil-to-coil consistency).

5. Surface inspection standard (define acceptable scratch depth/area; oil level if relevant).

6. Edge condition verification (burr height and slit quality).

For long-term sourcing, ask for process consistency documents (e.g., rolling/slitting control plan). This is especially helpful when you run automated winding lines.

5) Buying and sourcing tips for stable supply and better yield

Bulk buyers of aluminum strip coil typically optimize total cost by reducing winding scrap, rework, and insulation damagenot only by negotiating the lowest price per ton.

Practical sourcing tips:

Define application clearly: transformer type (distribution/power), winding method (foil/strip), and insulation system (paper/film) all influence edge and surface requirements.

Specify packaging: moisture barrier, rust/oxidation prevention, corner protection, and pallet strength for long-distance shipping.

Ask for coil traceability: heat number, coil number, and slitting batch records simplify claims and corrective actions.

Confirm coil weight and handling: match your decoiler capacity and line uptime goals.

Pilot order first: validate winding behavior (cracking, springback, tracking) and electrical results before annual contracts.

Quick RFQ template (copy into your purchase inquiry)

Product: aluminum strip for transformer windings

Alloy/temper: 1050/1060/1070, O (or specified)

Thickness width: mm mm

Tolerances: thickness , width , burr ___

Coil ID/OD & coil weight: / , ___ kg

Surface/edge: slit edge deburred, clean surface, insulation-safe

Testing: composition + conductivity (%IACS) + mechanical + dimensional report

Packaging: moisture-proof + edge protection + export pallet

When these details are standardized, bulk purchasing becomes more predictableand your winding yield improves with fewer insulation defects and coil build variations.

Original source: https://www.aluminumstrip24.com/news/aluminum-strip-for-transformer-2026-01-15.html

Tags: aluminum strip for transformer, transformer winding aluminum strip, aluminum strip coil, electrical grade aluminum strip, 1050 1060 1070 aluminum strip,

Previous: Aluminum Strip for Insulation

Next: Aluminium Strip Ceiling